We’re here to transform air travel

20th Feb 2023 | In News | By Mike Richardson

Set to make all-electric flight a reality by offering geared and direct-drive electric propulsion and battery solutions, Evolito is revolutionising electric air transportation. In a Q&A session, Evolito’s CEO, Chris Harris reveals more.

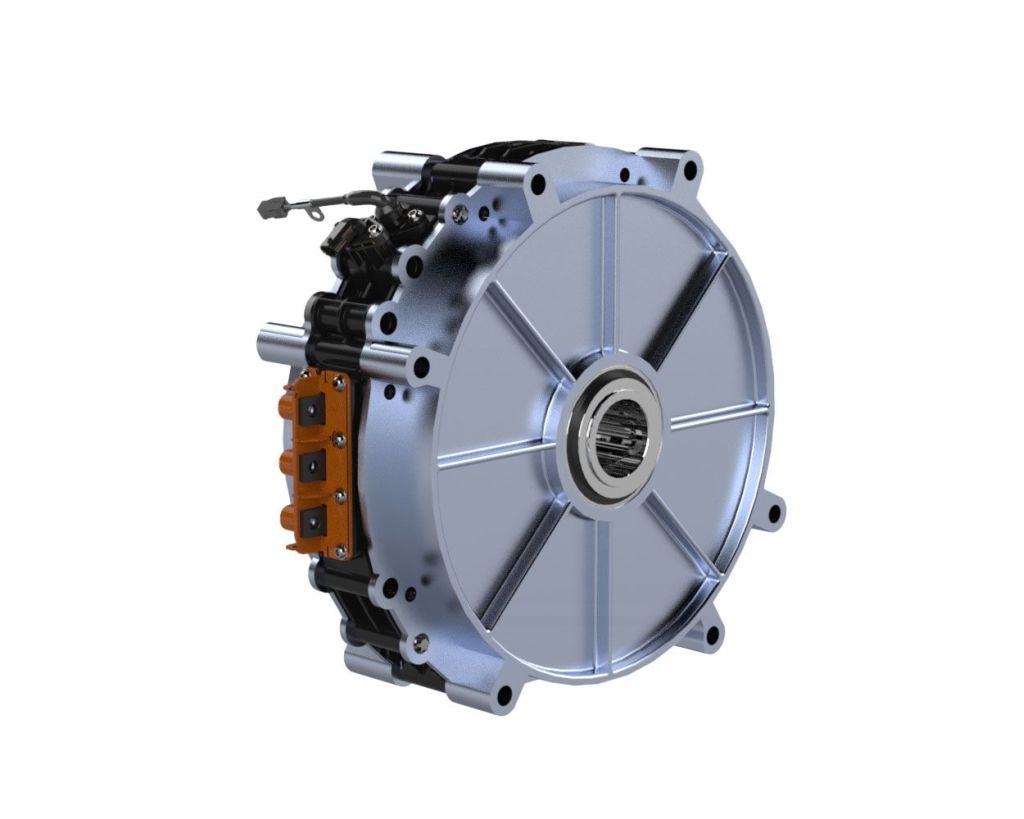

Evolito supplies high-performance, low-weight axial-flux motors and controllers that are said to be smaller, lighter and with a higher safety factor than any other competing electric propulsion technology. Evolito’s products enable a range of new electric propulsion applications, helping to accelerate the aerospace industry’s move towards net zero.

Q) Firstly, tell me about your background and role at Evolito.

When I joined YASA back in 2011, I didn’t anticipate the automotive sector being the lead opportunity for our technology. We knew the benefits that attracted automotive OEMs - YASA’s world-beating power to weight ratio - would be even more valuable in aerospace applications. Prior to the acquisition of YASA by Mercedes-Benz, we spun out YASA’s aerospace division as a new company - Evolito.

I want to be clear: this isn’t about transplanting automotive technology into aerospace: we’re leveraging our experience of automotive electrification and series production and a technology that’s already robust and designed for scale. It’s a very disruptive and innovative approach for aerospace. We aim to provide best-in-class products that meet all the aerospace safety and regulatory requirements, but at the cost and scale required by the automotive industry.

I see my role as developing the strategy, the technology and the team to meet aerospace’s emerging electrification market’s requirements. This isn’t set in stone; it’s in constant flux, so being agile is the key. My goal is to deliver the propulsion solutions OEMs and airframers need and being able to scale to volume when the market requires.

Q) How far along the path are you in making electric aircraft a reality?

In terms of the path to mainstream commercialisation of electric flight, we see an emerging market for both hybrid and pure electric aircraft, but we believe they will grow at different rates. There are several challenges to overcome before the eVTOL market can become mainstream. The barriers to entry for hybrid aircraft are lower than for eVTOL. As a result, we’re developing products to meet both hybrid and pure electric aircraft markets.

The core products we’re developing are e-motors based on our proprietary axial flux motor technology and motor control units (MCUs) - the power electronics that sit between the energy source and our e-motor. We’re also developing integrated propulsion solutions incorporating our e-motors and MCUs.

We’re taking the learning from YASA in terms of design for volume manufacture and combining this with the aerospace experience grown within the Evolito team to deliver e-motors and MCUs that meet all the necessary aerospace requirements and can scale to volume quickly when we see the market demand growing.

We have access to all YASA’s manufacturing IP, patents, processes and know-how which enables us to install a production line for our e-motors that can deliver quantity at the necessary quality levels to meet aerospace requirements repeatedly in production.

We’re also putting in place the necessary design and production organisation to enable certification of our products and we have strong and growing commercial relationships with general aviation OEMs, airframers and emerging eVTOL companies.

We anticipate delivering first samples of both our next generation axial flux e-motors and MCUs later this year which will be used for internal testing at Evolito and testing at customer sites. We also anticipate seeing our e-motors and MCUs in experimental aircraft within the next two years. We’re approaching the market in a similar way to the path I previously took through automotive electrification at YASA.

Q) Tell me about your acquisition of Electroflight at the end of last year?

We acquired Electroflight because it gives Evolito the capability to understand and address our customers’ challenges from a complete system level, including motor, MCU and battery. There are several challenges that need to be overcome from a battery perspective to enable growth of the all-electric aircraft market. This isn’t just about cell technology - there’s an infrastructure challenge and an ecosystem challenge that need to be solved too. Following this acquisition, our vision is to deliver complete propulsion systems. We know battery systems are going to strongly influence market adoption of electrification in the aerospace sector. Electroflight gives us the ability to address some fundamental industry challenges.

Q) What kinds of motor and battery power performance demands are placed on you by today's airframers?

Safety and the power to weight ratio of the electric propulsion unit (EPU) are the biggest drivers of demand from customers. Best-in-class competitor power-to-weight ratios right now seem to be around 7kW/Kg, whereas we’re aiming to deliver 13kW/Kg with our first products. Our axial-flux technology has a clear roadmap to even greater power to weight ratios in the future.

The ability to deliver best-in-class performance at a systems level at the same time as meeting aerospace safety and quality standards at competitive pricing will be critical to enable the acceleration of electrification in the aerospace sector. We understand these challenges and believe our proprietary e-motor technology and systems capability put us in a very strong position to meet these demanding new customer requirements.

Q) Do you enjoy healthy R&D funding and support from organisations like the Aerospace Technology Institute (ATI)?

We have received great supported from the ATI. For example, we’ve secured a grant which is helping us to develop core e-motor and MCU technologies for standalone and integrated products for the general aviation and emerging eVTOL markets.

The ATI is a great organisation and is vital to enable the growth and delivery of innovative technology within the aerospace sector within the UK. That said, it currently tends to be focused on themes such as hydrogen for example, where perhaps it could be more impactful if it broadened out that focus.

The UK is brilliantly positioned to be a leading global hub aimed at delivering the innovative, disruptive technology which is required for the wider adoption of electric flight. We have all the ingredients right here, and if Government support can be more broadly-focused to match the wider industry needs, it’s a massive market opportunity.

Q) When in the future do you foresee the tipping point for full short-haul electric aircraft adoption?

We think hybridisation of fixed-wing and electric conversions will be the early market opportunities for electrification. This is similar to the path that electrification took in the automotive market 10 years ago. We expect to see early hybrid opportunities emerge where the electric motor component is used to enable quieter take-off and landing and help reduce emissions in urban spaces.

One of the major challenges remains with batteries. eVTOL aircraft will initially start at a 20-30 mile range due to the limitation of current battery technology. This will likely limit market adoption. Ranges from 100-150 miles would be required to enable first intercity routes to be viable and battery life will also be a critical issue for the economics of such aircraft. In addition, the infrastructure to support these aircraft needs to be put in place. Only when these issues have been addressed will we see significant growth in the market for eVTOLs.

Q) What type of motor and battery technology is gaining the most traction in the aerospace industry?

We believe Evolito’s proprietary axial flux e-motor technology is ideally suited to aerospace applications as it offers significantly higher power and torque densities than conventional radial flux motors on the market today.

One area that we believe needs to be addressed by suppliers to enable the eVTOL market to reach its forecast growth potential is the ability to scale with competitive pricing. We believe Evolito is well-positioned to meet these new requirements for the aerospace industry by leveraging the experience gained by YASA in scaling to volume in the automotive market.

Q) Much is being done to reduce the weight of materials and components in aircraft, yet motors and batteries are still heavy?

Evolito’s e-motors and EPUs offer world-beating power to weight ratios and this is the biggest driver of demand from customers. Our best-in-class competitors right now are offering around 7kW/Kg, where we’re delivering 13kW/Kg today with a roadmap to even higher performance. This is important because customers want reassurance that a supplier can continue to meet their changing requirements as the market matures and evolves.

Regarding batteries, Electroflight gives Evolito the capability to address the industry challenges from a whole system level including the e-motor, MCU and battery. This isn’t just about cell technology - there’s an infrastructure challenge and an ecosystem challenge that need to be solved too.

Q) What really differentiates and sets you apart from the competition?

Our core axial-flux motor technology is highly differentiated, delivering market-leading power-to-weight ratio and offering system level advantages to our customers. It’s also already been proven in aviation applications, such as the award-winning ACCEL project and automotive applications by one of the world’s most demanding premium automotive OEMs, a unique launchpad.

Our acquisition of Electroflight last year means we now have complementary capabilities in battery design and manufacture. We can solve customer challenges by offering best-in-class complete powertrain solutions. Our team’s experience in design, manufacturing and future-proofing electrification technology sets us apart in this industry.

Q) Finally, where do you see the biggest business challenge coming from in 2023?

We have a clear strategy and product roadmap across both the general aviation and eVTOL markets, so 2023 is about delivering first samples to our customers and building out the capability to deliver certified EPUs, motors and MCUs. Our plans for growth are ambitious and we’ve got the financial backing in place to support those plans.

Our biggest challenge this year will be hiring the high quality talent we need to grow the business, but we have got off to a great start in January and are confident we can fill the positions we require with high calibre candidates to meet our ambitious business goals.

We started with five employees when we spun out in July 2021 to over 130 employees now. 60% of our headcount comes from the aerospace industry with around 30% coming from automotive. We believe the combination of proven automotive electrification experience and deep aerospace sector knowledge is a very powerful combination to be bringing to this high-growth market right now.

Consider a free digital subscription

If you find this article informative, consider subscribing digitally to Aerospace Manufacturing for free. Keep up to date with the latest industry news in your inbox as well as being the first to receive our magazine in digital form.