Axes of power

20th Jun 2018 | In News | By Mike Richardson

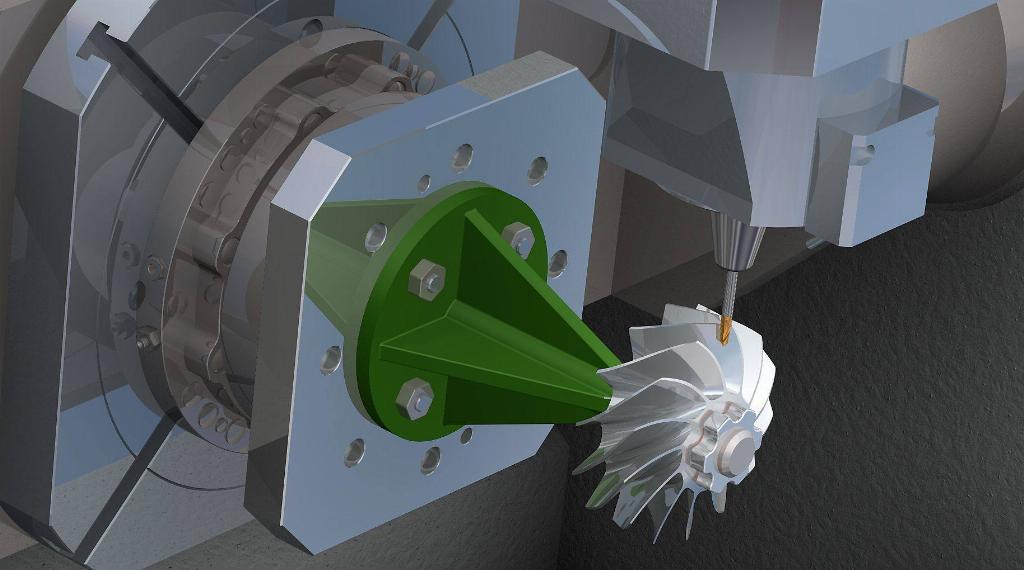

Dealing with 5-axis machining isn’t a simple process in any industry, but it gets especially interesting in the realm of aerospace. When we’re talking about subtractive manufacturing in general, you have to consider everything from your material and workholding, to your tooling and the toolpaths to get to your finished part.

Adding more axes not only complicates the selection process for toolpaths and feeds-and-speeds, but also the machine itself. There are a lot of things to consider when looking for a 5-axis CNC machine for milling in the aerospace industry, and the options might not be as intuitive as you think.

Why 5-axis machining for aerospace? One of the biggest reasons 5-axis machining is so prevalent in the world of aerospace is machine set-up. The parts often have complex geometries that don’t easily lend to 3- or 4-axis operations. While many of the parts might be possible without 5-axis machining, you’d have to continuously re-fixture your part just to get the geometry correct.

A perfect example of this is NASA’s Orion bulk head, which is domed near the heat shield. It’s a big forged piece of aluminium and all the pockets are normal to the surface, so you wouldn’t be able to get those angles with any other operation.

Another key consideration is weight reduction – you’re building a machine that flies, after all. More often than not, the goal is to find the best way to get the most strength with the least amount of weight. This is a major factor in defining all the weird geometries in aerospace manufacturing, and to that end, the need for 5-axis machining.

Defining your work envelope

The aerospace industry has a broad array of parts, components, and structures that require varying levels of machining, moulding, and even additive manufacturing. Defining your work envelope before buying a machine is vital to making the right choice. Some machined parts are massive, such as fuselage sections. 5-axis machining (or even six or seven) is necessary for this type of machining, but the real catch is that the machine itself ends up being the size of a building.

In situations like this, every milling machine is custom-built for a specific part, and the machine is rarely re-used once production of that particular part stops. Those machines are typically in operation for five to ten years, so once the part is no longer made, the technology has advanced so much that it’s more efficient to just upgrade to a new machine. Even if it costs $10 million for just one of those new machines, you’re going to make it up in time savings and production.

There is plenty of work to be done with smaller work envelopes as well. 5-axis machines that aren’t made as one-off production machines are usually off-the-shelf tool room-style machines and are typically used in R&D centres of aerospace organisations. That’s where they’ll reconfigure the machines a lot to do different parts, including SkunkWorks or Boeing’s Phantom Works. These off-the-shelf machine tools can also be used for the production of smaller parts, such as landing gear – which is still a large component that can reach the size of a decent office – but the principles stay the same.

Another key element to defining your work envelope is considering workholding and the actual cutting process. Again, aerospace presents some very odd – or uniquely-shaped parts, which can be even harder to hold and then actually machine. Once you’ve considered your part’s size, only then can you plan how it will be held and the tools needed for machining. If you’re dealing with cumbersome workholding or long tools, these elements need to be considered when determining the size of the machine.

The importance of uptime

When it comes to the aerospace industry, you’re looking for which machine can produce the tolerance of part you require, in the time that you want – this is very specific to the part or type of part that you’re creating. Once you know your work envelope and the tolerances you need to meet, the selection of machines will reduce, but there’s usually still plenty of choice.

The logical next step would be to look at the price. Since, at this point, you’re only looking at machines that fit your tolerances and your work envelope, comparing prices is the intuitive thing to do. But that’s wrong!

Determining what machine has the best uptime can be as important as metal removal rates. If your machine is down, you’re making no parts, which is certainly less than if you just had a slow (yet reliable) machine. Having spares to repair the machine without a service technician can certainly tip the decision. So, if several machine tools can all meet your criteria, then it comes down to which machine is least likely to break down and/or if it does break down, which can be repaired the quickest.

The price is right

The cheapest choice is rarely the best choice. When the machine isn’t producing anything – when it’s going from one toolpath to another, and not actually touching your part at all (rapids) – that time is huge. When you’re talking only ten seconds of off-part motion and you have another machine that can do it in two to three seconds, adding that up for a machining operation that takes four to five days for one part can result in up to twelve hours of lost time (depending on the operations and your part, of course).

When you’re dealing with five different axes of movement, the machine can get wrapped around itself when trying to get into various nooks and crannies of those odd-shaped parts. Determining what kinds of angular limits, the machine has is therefore key to making your rapids as fast as possible – if your machine needs to unravel itself from a weird angle on a part, that is all off-part motion.

Once you’ve determined machines that can handle your work envelope and tolerances, the next step to picking a machine comes down to speed. That’s why machine rapids are such a bragging point. Not just that companies can make parts faster, but that means that they are making more money. In this same vein of thinking, determining which machines have better removal rates for the materials you’re planning on machining should weigh your decision. Price is of little concern when value is achieved elsewhere.

In the end, every application is going to be unique, but these are the key factors I’d recommend considering before deciding on which 5-axis machine is right for your aerospace part.

Consider a free digital subscription

If you find this article informative, consider subscribing digitally to Aerospace Manufacturing for free. Keep up to date with the latest industry news in your inbox as well as being the first to receive our magazine in digital form.