An efficient ‘root’ for turbine blade production

31st Jul 2017 | In News | By Michael Tyrrell

The continuing growth in the aerospace manufacturing industry offers manufacturers tremendous opportunities for those that are agile enough to take advantage.

Major aircraft manufacturers predict that the global aircraft fleet will double in the next 20 years, whilst at the same time, a range of regulatory requirements that are driven by the need for passenger safety and by ecological considerations, present new challenges for component suppliers.

The global nature of the aerospace manufacturing industry and the growing complexity of supply chains means that it is more important than ever to be able to trace individual parts through manufacturing processes, and also to supply supporting quality assurance documentary evidence. When looking to conform to these stringent demands, and to achieve greater levels of efficiencies, today’s manufacturers are looking to do more than just procure another machining centre, they are seeking all-embracing, integrated manufacturing systems.

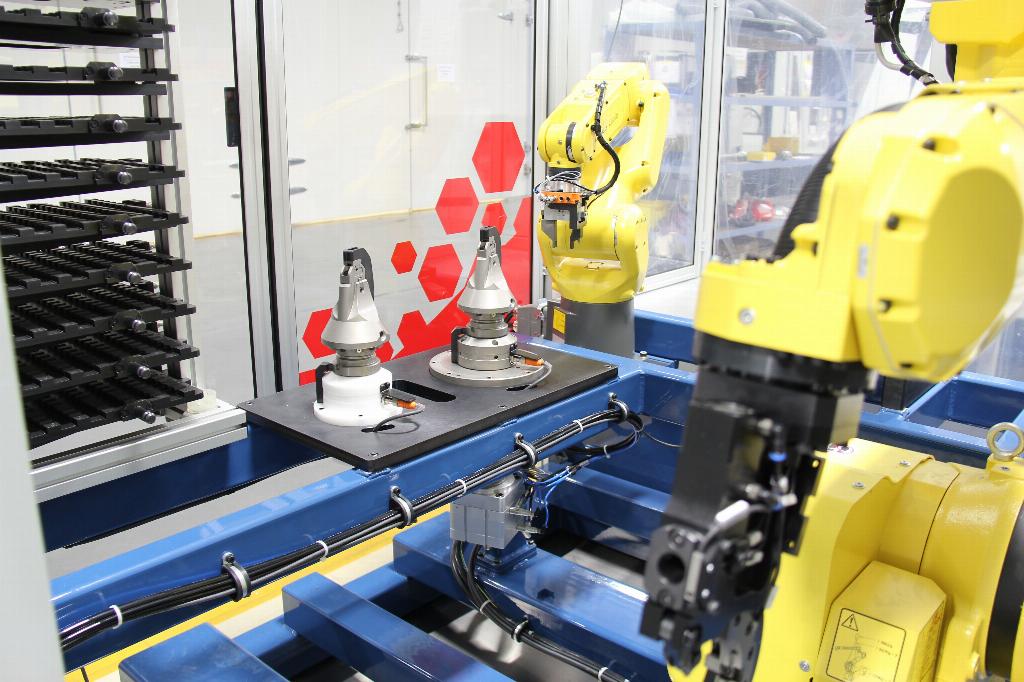

ANCA, a global leader in the manufacture of highly flexible universal CNC grinding machines, is successfully delivering new solutions that address these wide-ranging needs. For instance, by the use of a robot, ANCA’s TXcell grinding cell can automatically load, not just workpieces, but also grinding wheel packs, resulting in levels of rotary cutting tool production efficiencies that were unimaginable just a couple of years ago.

Building on this success, by incorporating a second robot into the TXcell, ANCA has delivered machines to customers that undertake applications that require additional ancillary operations. ANCA TXcell sales, featuring a two-robot option, have been made to a range of users in areas where undertaking additional operations in a single setup brings much greater efficiencies.

The root of the matter

In a recent example, ANCA teamed up with other key suppliers to deliver an effective solution to the root form grinding of jet engine turbine blades.

“When performing test grinding with customers, we knew that our TXcell represented an excellent basis for fast and accurate turbine blade, root form grinding operations,” explains TX and EDGe product manager, Duncan Thompson. “However, in this competitive market, we sought to offer greater value to our customers beyond the grinding machine itself.” Tasked with this challenge, ANCA engineers worked closely with customers to deliver an all-encompassing manufacturing cell that would do much more than just the root form grinding of turbine blades.

The first part of the solution worked on by ANCA was the automatic part handling of the turbine blades to enable unmanned production. As turbine blades represent a non-uniform shape traditional processes involve encapsulating them in a soft alloy, making them easier to hold during grinding operations. As encasing turbine blades is a separate, time consuming process that has to be managed, ANCA engineers designed an ingenious fixture for securely holding turbine blades, allowing automatic loading. The loading of blades into the fixture was made possible with the addition of a second smaller robot to the TXcell. The original large robot remained responsible for changing wheel packs and now also for loading the fixture and blade together into the TX grinding machine.

The use of two robots in the cell opened up a wide range of possibilities for many other processing tasks. A major advantage was the ability to achieve part serial number tracking. This task was realised with the addition of a Cognex camera and an Automator laser etch system to the TXcell. Before grinding, the turbine blade serial numbers are able to be read by the Cognex camera and the data transmitted to the laser etch for post grinding ID marking.

By adding a Renishaw Equator measuring system to the cell a further advanced capability was added - post process part gauging. In this automated operation, the second robot unloads a finish ground blade and presents it to the Equator which then gauges the part against a traceable master. Good parts are returned to the pallet by the robot, and failed parts are placed in the appropriate over-size or undersize bin.

Meeting production rates

On proving the system’s capability to perform unmanned accurate turbine blade root form grinding, ANCA engineers were then tasked with delivering the required capacity. Again, using the flexibility of the TXcell’s large robot, an automatic pallet change system was developed extending the system’s available capacity from a single pallet to ten pallets.

The addition of these invaluable functions meant the TXcell was now not only grinding the required parts unmanned over a weekend, but also delivering them with individual serial numbers that could be validated against a fail-safe QC checking system. According to one satisfied customer, the resulting comprehensive lights-out production system “went above and beyond the expectations we initially started out with”.

Thompson concludes: “Because of the great success of the dual robot TXcell turbine blade application, I anticipate we will be able to deliver a range of highly efficient solutions that provide cost savings and quality improvements to a range of volume component grinding applications.”

ANCA’s highly efficient, dual robot TXcell will be on demonstrated in September at the EMO Hanover 2017 exhibition, Hall 6, Booth K59.

Consider a free digital subscription

If you find this article informative, consider subscribing digitally to Aerospace Manufacturing for free. Keep up to date with the latest industry news in your inbox as well as being the first to receive our magazine in digital form.