Aero advances in the spotlight

5th Oct 2016 | In News | By Michael Tyrrell

Back in 2009 the Advanced Engineering Show was solely dedicated to featuring advances in the world of aerospace manufacturing. Since then it has grown to include three more co-located shows Automotive Engineering, Composites Engineering and Performance Metals.

This year, the two-day event is being held on November 2nd and 3rd at the NEC in Birmingham in Halls 2, 3 and 3a of the exhibition centre. The 2016 edition is being managed by Easyfairs, a global event organiser which acquired the show from its founder Ian Stone and UK Tech Events last year.

Event director Katie Crocombe says Easyfairs intends to build on the successful formula that the show has benefited from so far.

“It is a unique trade event mainly because it is open to everybody throughout the supply chain, whether you are a start-up, SME or well-established company within the engineering sector. That’s also one of the main reasons there’s a real sense of innovation. One of the main features we have continued is the very strong relationships we have with the membership bodies and organisations from the various industries involved in the show. They have really contributed to how it has evolved on the show-floor.”

Creating a community

This industry involvement from groups such as the ADS, Composites UK, EEF, UKTI, Midlands Aerospace Alliance and Northwest Aerospace Alliance has helped to build a sense of community among all the participating bodies, according to the organisers.

“There is a real buy-in into the concept from everyone, whether they are associations, academic institutions or exhibiting companies,” Crocombe continues. “The show also gives exhibitors the opportunity to see other companies from parallel sectors that they wouldn’t normally get to see at a sector specific trade event. That crossover factor has huge benefits.”

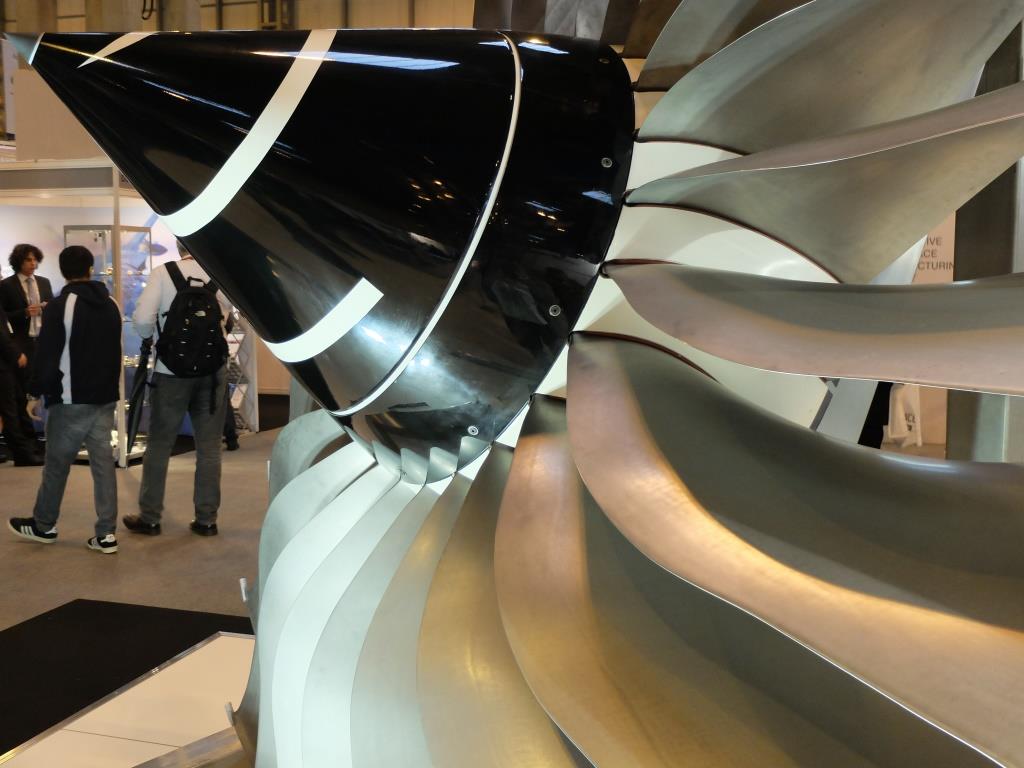

The Aero Engineering zone will feature some of the most advanced aerospace technology available.

Jeremy Whittingham, head of marketing for Advanced Engineering comments: “The UK aerospace industry is at the heart of delivering new technology to ensure that the next generation of civil aircraft is cleaner, quieter and more efficient than ever.

“Aero Engineering was the founding zone of the show. Since then it has grown organically along with the addition of each co-located zone, but it is still going strong. It includes subject areas such as design and development, testing, assembly, inspection, so it means exhibitors can meet engineers and decision makers who want to source either new materials, processes and solutions. Last year we had attendees from Airbus, Bombardier, BAE Systems, Moog, Marshall Aerospace, UTC and Safran to name just a few of the key industry stakeholders coming through the doors.”

Among the exhibitors in Aero Engineering are key industry suppliers and research institutes who are committed to finding new developments and innovations in a wide range of areas in the aerospace industry, including aerostructures, power plants, R&D, materials and production.

Whittingham continues: “This year we will have a bigger partnership with the ADS which is very important for Aero Engineering. They will be staging SC21 case studies and presentations as part of the seminar programme.”

Innovation advances

A key feature of Advanced Engineering is developing and promoting new technology in all the sectors associated with the show; whether it is through the show’s open conference programme, which offers attendees the latest insights into industry from expert speakers, or exhibitor zones which feature the latest products and prototypes from many areas of engineering.

A typical example of the focus on new technology is the Enabling Innovation hub. Sponsored by global automotive supplier Magna and supported by the Knowledge Transfer Network (KTN), the hub will showcase some of the most innovative technology from start-ups and SMEs.

This year a new development will be a competition for a group of selected innovators who will be featured at Enabling Innovation. The shortlisted entries will exhibit with support from Magna. The most innovative technology from whatever engineering background will also win a £5,000 prize courtesy of Magna.

As well as entering the competition innovators and technology specialists can exhibit in the zone themselves or set up meetings with representatives from Magna’s R&D team for funding and technical support opportunities.

Whittingham explains: “With Enabling Innovation we are better placed than most trade shows to help companies capitalise on the innovations between R&D and the industry. We need to be a catalyst to help encourage R&D being commercialised.”

This year the show is partnering a number of other events related to the industry also at the NEC in November.

A major development is the involvement of the Institute of Mechanical Engineers (IMechE). The Institute will be holding two, one day seminars during Advanced Engineering. On November 2nd the seminar programme will be dedicated to Aviation Aerodynamics with speakers from companies such as Airbus, who will be speaking about Clean Sky 2 and natural laminar flow flight testing and Rolls-Royce, discussing its UltraFan engine and Boundary Layer Ingestion (BLI) propulsion on large aircraft. There will also be talks from Reaction Engines, QinetiQ and the European Space Agency.

On November 3rd the Seminar will be dedicated to brakes and enhancing their performance with speakers from companies such as Jaguar Land Rover, Honda, McLaren Automotive and Bentley.

Advanced Engineering will also be held in partnership the Smart Factory Expo at the NEC. The Expo will focus on the latest interconnectivity advances in manufacturing and the development of Industry 4.0.

“This is a very hot topic at the moment,” says Crocombe. “The conference is aimed at the executive level, and focuses on the impact the Smart Factory is going to have on manufacturing in the future. Having those kind of decision makers in and around the show discussing the future of manufacturing at our event is a great development.”

In the zone

The event’s format allows attendees and exhibitors to encounter all the latest advances in manufacturing and engineering. Another zone of interest for aerospace practitioners is the Performance Metals show.

Whittingham says: “As well as covering traditional areas such as lightweight aluminium, titanium and magnesium it also focuses on developments such as powder metallurgy which is associated with additive manufacturing. We have several presentations regarding additive technology during the event.”

The show seems to reflect the positive outlook UK manufacturing has tried to embrace after the post Brexit vote if booking number are anything to go by.

“It does seem that it is business as usual,” says Crocombe. “The strongest indication of a show’s success is shown by how many exhibitors come back year on year. If you look at bookings for 2016 we have had the highest return of exhibiting companies that we have ever had.

“We also try to facilitate networking around the show and one of the best ways to do this is the one-on-one meetings that exhibitors have on their stands. To help this we have the pre-show portal that they can access, to book a meeting. It is a great way for exhibitors to make the best use of their time. We also have a mobile phone app that allows visitors and exhibitors to access data and be proactive with that information. It’s all about helping companies to do as much business as possible.”

So according to Easyfairs, the show can go from strength to strength based on the foundations laid down by its originators.

“It has proved to be incredibly successful with fantastic growth and enthusiastic support from the industry,” concludes Crocombe. “There’s not much more you can ask from a trade event. Hopefully as a bigger organisation we can provide more support so the behind the scenes elements will make it an easier experience for exhibitors and visitors.

“We wanted to make improvements but still keep the essence of the show that has made it a success. Advanced Engineering is marketed on a manufacturing zone basis but also a co-ordinated overall event which we believe is more than the sum of its parts. There is a very successful overlap between them all. We like to think it is where attendees benefit from getting the chance to meet the familiar and the unfamiliar.”

Consider a free digital subscription

If you find this article informative, consider subscribing digitally to Aerospace Manufacturing for free. Keep up to date with the latest industry news in your inbox as well as being the first to receive our magazine in digital form.