Advanced Engineering 2018: Aero innovations times ten

5th Oct 2018 | In News | By Michael Tyrrell

Advanced Engineering 2018 incorporates not only the latest developments in aerospace engineering, but the whole scope of UK manufacturing. Now in its 10th year the show has become one of the biggest events in the UK manufacturing calendar. Show organisers, Easyfairs tell Ed Hill what visitors can expect to see.

When the Advanced Engineering Show was first launched the UK’s manufacturing prospects looked pretty gloomy. Companies were having to deal with the fallout of the global financial crash and offshoring work, traditionally carried out by UK engineering subcontractors, was the growing trend for OEMs looking for cheaper Far Eastern alternatives.

However, that time also corresponded with an aspiration to promote the high-end engineering capability in which the UK could still justifiably claim to be a world leader.

Aerospace is a key sector in the UK’s advanced engineering landscape so unsurprisingly it was one of the sectors that the show first focused on. Since then the event – which this year will be held on October 31st and November 1st at the NEC Birmingham – has grown not only to incorporate the Aero Engineering zone but also Composites Engineering, Automotive Engineering, Performance Metals, Connected Manufacturing and, both new for this year, the UK Contract Manufacturing and Nuclear Engineering zones.

Jeremy Whittingham, head of marketing for the show, which is run by Easyfairs, comments: “Our 10th anniversary is a great milestone because it not only helps increase the profile and exposure of the show, it also coincides with the Government’s ‘Year of Engineering’, which is intended to attract young people into the sector. One of the reasons the show has successfully grown over the last ten years is because there really is something to celebrate about modern engineering and manufacturing in this country.”

With nearly all the floorspace booked in halls 2,3 and 3a of the NEC, more than 650 exhibitors are expected to be housed in the show’s dedicated zones. The event is anticipated to attract thousands of visitors including engineers, procurement managers and senior decision makers from large and small companies looking to explore the latest industry innovations, source new suppliers, and invest in the most up-to-date manufacturing technology, systems and services.

Opening up knowledge

One of the main features of the show is its Open Conference programme. Dotted around the show halls are six dedicated presentation areas linked to each manufacturing zone that offer high level insights and information from leading industry experts and organisations. These free to attend, Continuing Professional Development accredited talks are open to any visitor who registers for the show.

In the Aero Engineering Forum some of the topics covered in the presentations include: a keynote talk from the ADS on Aerospace 4.0 and the adoption of digital capabilities in the aerospace supply chain; Spirit AeroSystems discussing the development of a spoiler wing component for the Airbus A320; and the use of Graphene in aerospace applications from the University of Central Lancashire (UCLAN).

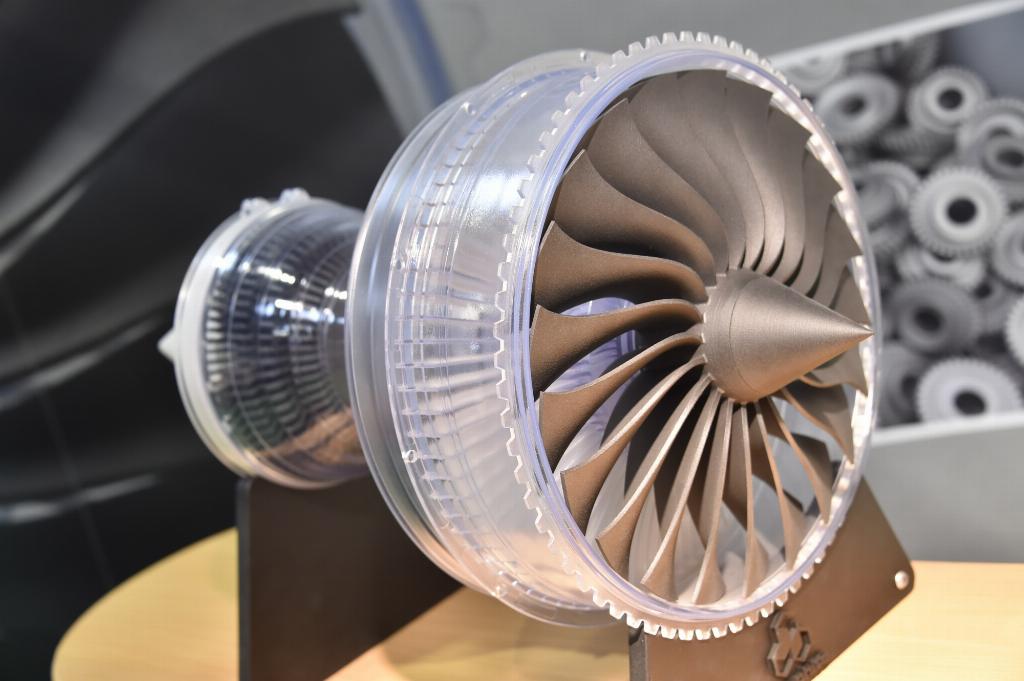

Other topics covered in the aerospace talks include additive manufacturing, applying big data to manufacturing, composites materials, drone development and electrification of power sources as well as the ADS’ SC21 continual improvement programme for aerospace suppliers.

“We wanted to bring more high-level input to the Aero Engineering Forum, that is why it is great to have the involvement of the ADS,” Whittingham affirms. “We believe this will also help to bring in additional high-level attendees. The ADS is very supportive of the show because it has a different perspective than a big airshow like Farnborough, for example. The manufacturing it focuses on affects companies both large and small from a very broad supply chain.

“The Open Conference programme has always been a strong element of the show. Most presentations are around 15-30 minutes long and the ethos has always been to give attendees case studies that they can relate to and find useful.”

Other aeronautical highlights at the show include an exhibit featuring the 3.5m wingspan Juno drone, the first Graphene skinned aircraft, developed by the UCLAN and the Prion Mk3 drone, a civilian market UAV capable of 12 hours flight before refuelling. The Prion Mk3 is designed for a wide range of applications, such as aerial surveys of windfarms, border security or humanitarian aid air drops in disaster areas. There will also be an Innovation Showcase zone where exhibitors at the show can promote some of their very latest manufacturing and engineering technology in a dedicated area.

One of the most popular features in the show halls last year was the Connected Manufacturing Zone which focuses on some of the latest digital manufacturing developments in production technology. This year as well as the many exhibitors, the presentations include topics such as: Leveraging big data to develop new revenue streams from Omron Electronics, Digital manufacturing and bringing connected enterprises to life by Rockwell Automation and creating the factory of the future from IBM.

“Terms like Industry 4.0 and The Internet of Things (IoT) are used a lot but many in the sector may feel it’s just applicable to the OEMs and Tier 1s who can spend millions of pounds on a robotic production line, but what do these developments mean for the small subcontractor? These presentations are a way to introduce SMEs to these concepts and how they can also benefit them. It may just be something as simple as new monitoring software that can shave seconds off a cycle time but save many thousands of pounds over a year.”

The latest engineering developments may be one of the biggest draws for Advanced Engineering 2018, but equally important are the business opportunities it offers. This year Easyfairs has introduced a new system that will help attendees and exhibitors get the most value from their time spent at the show.

Meeting made easy

AE Connect is the free to use online matchmaking tool that allows visitors and exhibitors to book meetings. It means those registered with the show can search its database to arrange appointments with key contacts prior to and during the show. Requests can be filtered by factors such as sector, job title or product interests.

“This is the first time we have introduced a system like this,” Whittingham explains. “We believe it will help OEMs, tier 1 and the rest of the supply chain meet the people or companies they really want to, based on their profiles. There is huge value in being able to see before the event some of the people and companies who will be attending and reach out to them with the prospect of a meeting.”

AE Connect works as an intermediary between show attendees allowing them to make contact confidentially, schedule and then confirm a meeting on the stands, meeting lounges or networking areas.

“It’s really like an electronic concierge service. Furthermore, during the show, we will have dedicated AE Connect staff who can help people get to their appointment whether it is on a stand or meeting area and chase and confirm meetings for those involved.”

So why has Advanced Engineering been successful in establishing itself as one of the biggest annual get togethers for the UK’s innovative manufacturing sector?

“After the financial crash in 2008 it’s almost as if there was a feeling that we needed to realign the UK economy and put more emphasis on engineers and engineering to compete in the world,” Whittingham concludes. “The show has grown organically out of that environment as various zones have been added and become much more than the sum of its parts. We are immensely proud of how it has developed over the years. We feel the NEC show has still not reached its full potential as we consider promoting other advanced engineering fields, such as embedded electronics and space.”

Consider a free digital subscription

If you find this article informative, consider subscribing digitally to Aerospace Manufacturing for free. Keep up to date with the latest industry news in your inbox as well as being the first to receive our magazine in digital form.