Accelerating with additive

22nd Nov 2021 | In News | By Mike Richardson

Curtiss-Wright Sensor UK’s operations department reveals how it has successfully integrated additive manufacturing into its production processes.

A long-standing customer of CREAT3D (Additive Manufacturing Specialists) Curtiss-Wright have been able to accelerate their additive capabilities through applications engineering, training and advice from CREAT3D, resulting in a flexible, functional solution that the team is reaping the benefits from on a daily basis.

Based in Bournemouth, Curtiss-Wright Sensors UK sits within the aerospace and industrial division of Curtiss-Wright Corporation. With a legacy dating back to 1903, the company specialises in the design and manufacture of high accuracy, flight critical components for the commercial and defence aerospace, business and helicopter and ground defence sectors.

“Additive makes such a huge difference to our manufacturing capabilities,” begins Curtiss-Wright Sensors’ senior manufacturing engineer, Andy Mainstone. “One of the biggest benefits is the speed of turnaround. It gives us flexibility to produce bespoke, complex products for our clients, and fast.”

The operations team design and produce technical documentation and tooling to support production and new product introduction (NPI) departments. A fast-paced, demanding environment - with daily tooling requests coming direct from operators and design engineers - the team has to be agile and responsive to provide creative, low cost and fast solutions for an array of engineering problems.

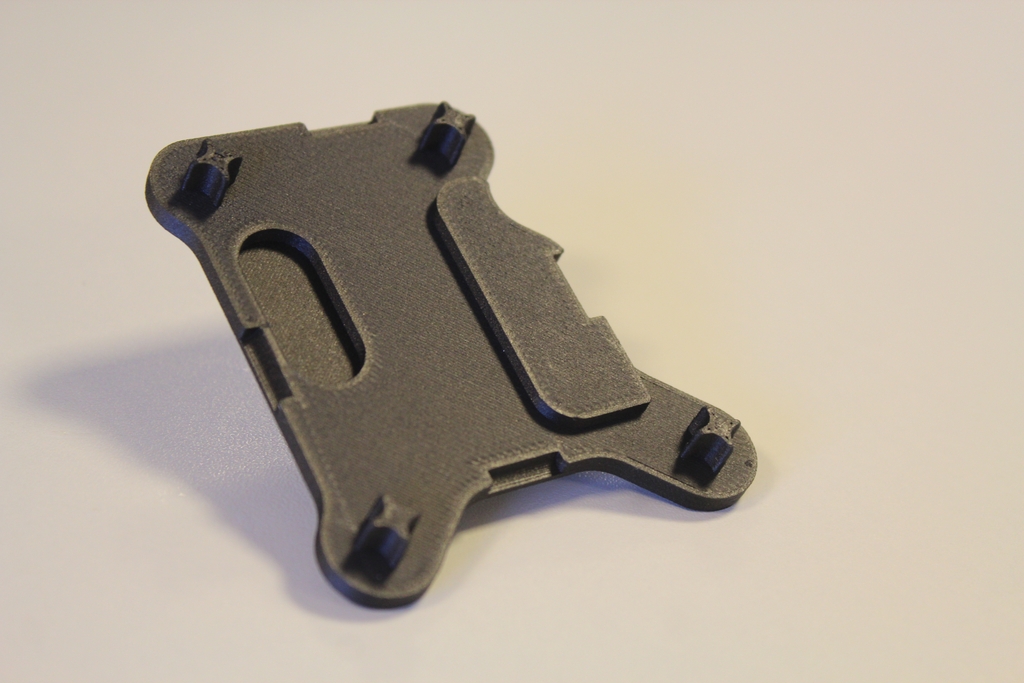

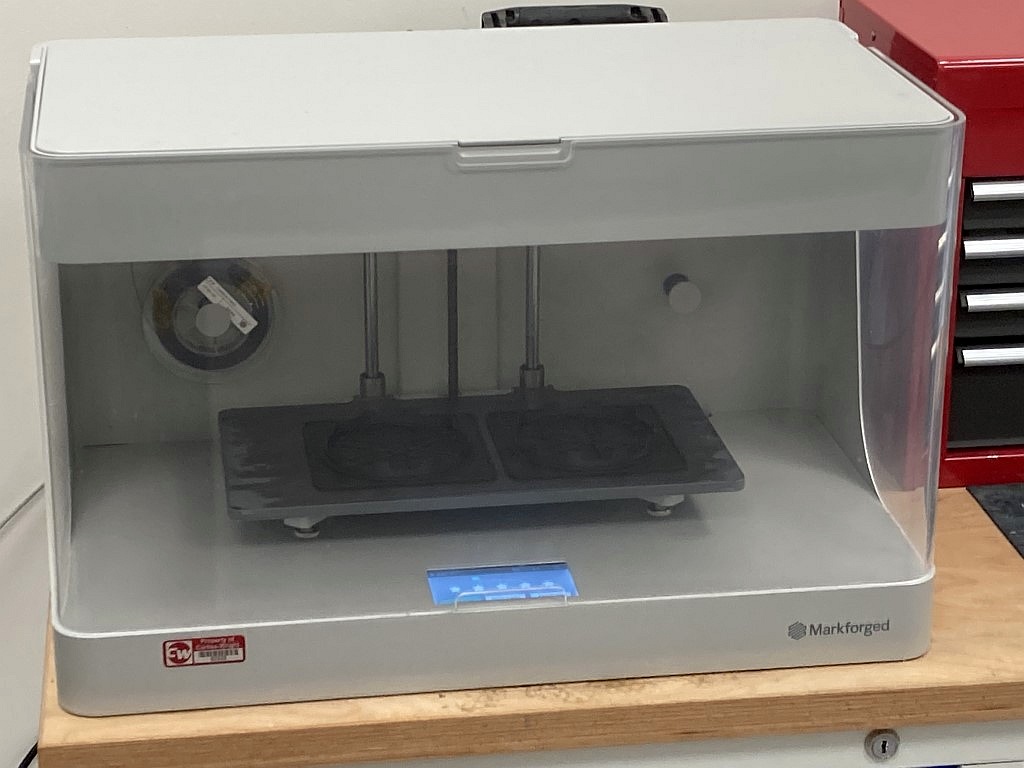

The team is using the Mark Two composite 3D printer from Markforged to produce 3D printed tooling on demand. Printing in Onyx (nylon with micro carbon fibres), a non-marring material. With the option to add carbon fibre reinforcements, the team is able to produce robust, high strength, quality tooling - within hours of the original request.

Meeting the challenges

Curtiss-Wright has a long-standing reputation for the pedigree of its products, excellent reliability and proven performance in supplying the aerospace sector. Given the nature of the industry and equipment to which the sensors are fitted, Curtiss-Wright faces three key challenges daily: 1) Sensors are made to order: All sensor products are made to order, with design and performance requirements specific to each individual client. An order may consist of a single component; 2) Small batch volume needs flexible manufacturing: Curtiss-Wright has to adapt their manufacturing processes regularly to manufacture small batches of sensors, typically from 1–50; 3) The tooling required for each job differs every time.

As each project is bespoke, the tooling needed in production and assembly must also be bespoke. In addition, there are legacy products and one-off product requests that require more complex production processes.

“The speed at which we can solve problems is superb,” says the company’s senior manufacturing engineer, Pete Netherton. “We are made aware of the problem in the morning and by lunchtime the operator has a bespoke tooling to use. It enables us to keep production moving. I don’t know how we managed before additive!”

In just over 2 ½ years of owning the Markforged Mark Two, the operations team has designed and printed over 600 different pieces of tooling. Ranging from assembly aids, brackets, orientation and locator jigs, to holding nests, blocks, covers, tools, clips, clamps, racks, trays and moulds, the applications are vast and ever-expanding.

Once the tooling has been printed, the CAD and print files are categorised and stored so that they can be easily accessed for repeat jobs - or in the future for legacy products. Furthermore, if a tool is lost or broken, it can be quickly reprinted from the system, reducing production line downtime and saving hundreds of pounds in using external CNC contractors.

“The cost savings have been huge,” explains Mainstone. “If we no longer used additive, our senior management would immediately ask us why we are spending so much money on tooling and why’s it taking so long.”

It all adds up!

The savings achieved from 3D printing tooling in-house resulted in Curtiss-Wright seeing a return on investment on its printer in less than two months.

The quality and accuracy of parts 3D printed on the Markforged printer, combined with the speed of turnaround and low cost to produce, has resulted in the operations team expanding additive applications to solve problems outside of tooling.

“The shopfloor is constantly surprised by the quality and speed at which our team can 3D print their requests,” explains Mainstone. “Previously, tooling requests may have gone unanswered, or were slow to resolve because they were cost prohibitive - or there was too much demand on the internal machine shop. Using our Markforged 3D printer, we can now deliver solutions to production the same or next day, whilst manufacturing is underway.”

With the Markforged 3D printer, the operations team complete the design in CAD and then send it to the printer.

“This gives us exactly what we want, much faster,” adds Mainstone. “We’ve learnt to design for additive, so we are getting the best result in the fastest and most economical manner.”

This streamlining of internal processes as a result of additive enables Curtiss-Wright Sensors UK to be even more agile and responsive to the customer demands. The company is now able to manufacture bespoke and complex sensor products at low volume. Combined with the additional benefits of reduced costs, reduced production line downtime and improved end product, means that additive manufacturing continues to become an indispensable engineering tool.

Consider a free digital subscription

If you find this article informative, consider subscribing digitally to Aerospace Manufacturing for free. Keep up to date with the latest industry news in your inbox as well as being the first to receive our magazine in digital form.